Warehouse KPI Template: The Secret Weapon Top Warehouses DON’T Want You to Know

Meta Title: Warehouse KPI Template: Boost Efficiency & Profits

Meta Description: Unlock the secrets of warehouse optimization with our comprehensive KPI template. Track key metrics, improve performance, and gain a competitive edge. Learn how to create a winning strategy today!

Introduction

In the cutthroat world of logistics, efficiency is king. Warehouses are the beating heart of supply chains, and their performance directly impacts profitability, customer satisfaction, and overall business success. But how do the top warehouses consistently outperform the competition? The answer lies in their strategic use of Warehouse Key Performance Indicators (KPIs). This article unveils the power of a warehouse KPI template, a secret weapon that can revolutionize your warehouse operations. We’ll explore the critical metrics, provide actionable insights, and show you how to create a data-driven culture that drives continuous improvement. Prepare to transform your warehouse from a cost center into a strategic asset.

What are Warehouse KPIs and Why are They Crucial?

Warehouse KPIs are quantifiable metrics used to measure and track the performance of various processes within a warehouse. They provide a clear picture of operational efficiency, identify areas for improvement, and enable data-driven decision-making. Think of them as the vital signs of your warehouse, offering insights into its health and well-being. Without these vital signs, you’re essentially flying blind.

Why are they crucial?

- Improved Efficiency: KPIs pinpoint bottlenecks and inefficiencies, allowing you to optimize processes and reduce waste.

- Enhanced Productivity: Tracking KPIs helps you identify areas where productivity can be boosted, leading to increased output.

- Reduced Costs: By streamlining operations and minimizing errors, KPIs contribute to significant cost savings.

- Better Inventory Management: KPIs provide insights into inventory levels, turnover, and accuracy, helping you avoid stockouts and excess inventory costs.

- Increased Customer Satisfaction: Efficient warehouse operations translate to faster order fulfillment and fewer errors, leading to happier customers.

- Data-Driven Decision Making: KPIs provide the data needed to make informed decisions about staffing, technology investments, and process improvements.

H2: Building Your Warehouse KPI Template: A Step-by-Step Guide

Creating a robust warehouse KPI template involves several key steps. This isn’t a one-size-fits-all solution; you’ll need to tailor it to your specific warehouse operations and goals.

Define Your Goals: What are you trying to achieve? Are you looking to reduce costs, improve order accuracy, increase throughput, or all of the above? Your goals will dictate the KPIs you track.

Identify Key Processes: Map out the key processes within your warehouse, such as receiving, put-away, picking, packing, and shipping.

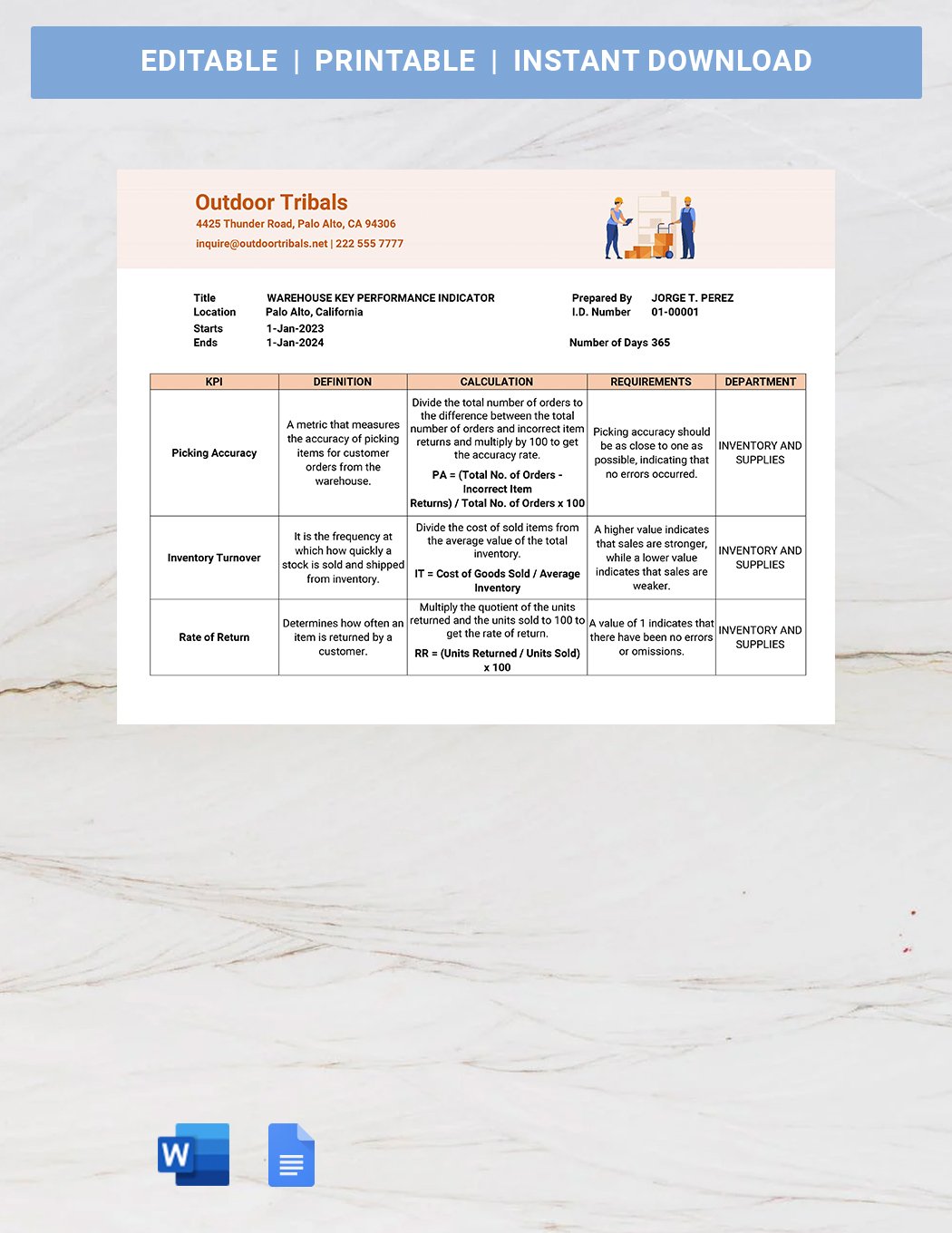

Select Relevant KPIs: Choose KPIs that directly relate to your goals and key processes. Here are some crucial categories and examples:

Receiving:

- Receiving Accuracy: (Number of correct items received / Total items received) x 100

- Receiving Cycle Time: Time from receiving a shipment to its arrival in the warehouse.

- Receiving Efficiency: (Total items received / Total receiving labor hours)

Put-Away:

- Put-Away Accuracy: (Number of items put away correctly / Total items put away) x 100

- Put-Away Cycle Time: Time from receiving an item to its placement in the storage location.

- Put-Away Efficiency: (Total items put away / Total put-away labor hours)

Picking:

- Order Picking Accuracy: (Number of orders picked accurately / Total orders picked) x 100

- Picking Cycle Time: Time to pick an order from start to finish.

- Lines Picked per Hour: Number of order lines picked per labor hour.

- Picking Efficiency: (Total lines picked / Total picking labor hours)

Packing:

- Packing Accuracy: (Number of orders packed correctly / Total orders packed) x 100

- Packing Cycle Time: Time to pack an order.

- Packages Packed per Hour: Number of packages packed per labor hour.

Shipping:

- On-Time Shipping Rate: (Number of orders shipped on time / Total orders shipped) x 100

- Shipping Accuracy: (Number of orders shipped with correct items / Total orders shipped) x 100

- Shipping Cycle Time: Time from order ready for shipping to the truck loading dock.

Inventory Management:

- Inventory Turnover: Cost of goods sold / Average inventory value

- Inventory Accuracy: (Number of items counted correctly / Total items counted) x 100

- Days of Inventory on Hand: (Average inventory value / Cost of goods sold) x 365

Labor:

- Labor Cost per Order: Total labor cost / Total orders processed

- Labor Productivity: Total units processed / Total labor hours

Establish Baselines: Before you can measure improvement, you need a starting point. Collect historical data for your chosen KPIs to establish baselines.

Set Targets: Based on your goals and baselines, set realistic and achievable targets for each KPI. Make them SMART: Specific, Measurable, Achievable, Relevant, and Time-bound.

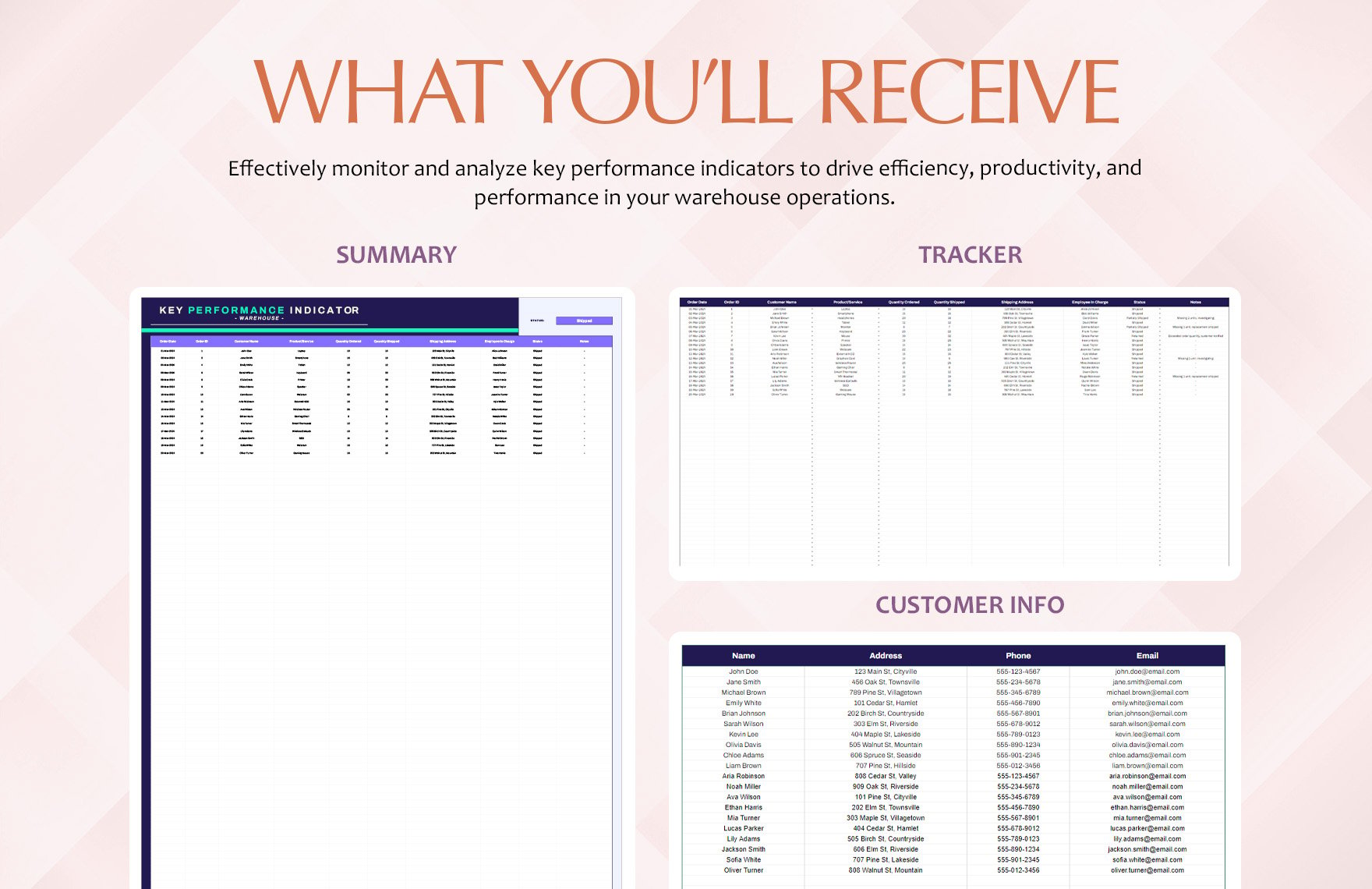

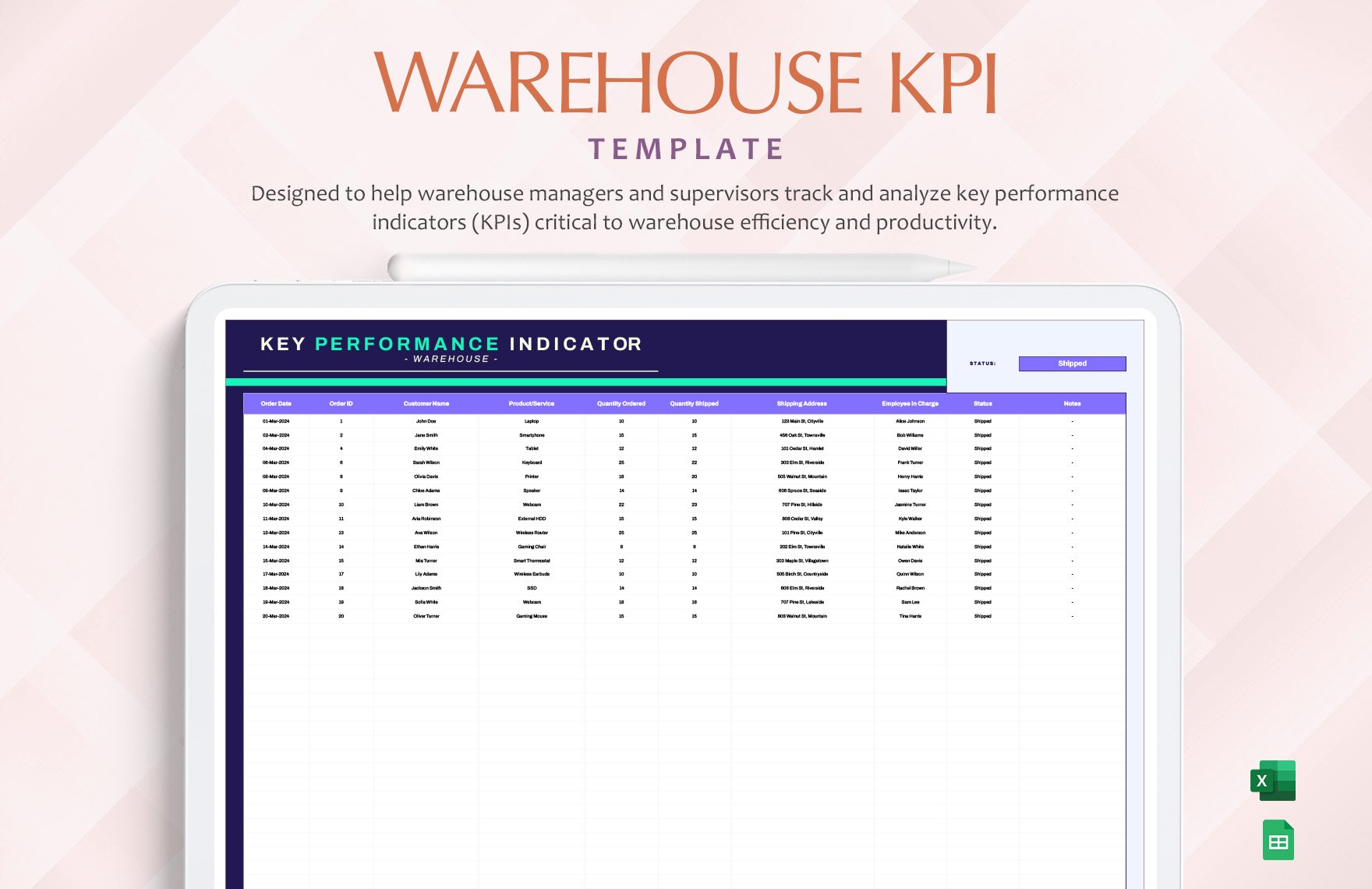

Choose Your Tracking Method: Determine how you will collect and track the data. This could involve spreadsheets, Warehouse Management Systems (WMS), or other software solutions.

Regularly Analyze and Report: Analyze the data regularly (weekly, monthly, quarterly) to track progress, identify trends, and uncover areas for improvement. Generate reports that communicate the findings to relevant stakeholders.

H3: Tools and Technologies to Support Your KPI Implementation

Leveraging technology can significantly streamline your KPI tracking and analysis. Consider these tools:

- Warehouse Management Systems (WMS): Link to a reputable WMS provider, e.g., NetSuite, SAP A WMS provides real-time data and automated tracking capabilities, making KPI monitoring easier and more accurate.

- Spreadsheet Software (Excel, Google Sheets): Excellent for smaller operations or initial implementation.

- Business Intelligence (BI) Tools: Link to a popular BI tool, e.g., Tableau, Power BI These tools offer advanced data visualization and analysis capabilities.

- Barcode Scanning and RFID Technology: These technologies improve data accuracy and speed up processes like receiving and inventory tracking.

H2: Real-World Examples and Case Studies

Let’s look at how some companies have used KPIs to achieve significant results:

Example 1: Improving Picking Accuracy. A mid-sized e-commerce company was experiencing a high rate of picking errors, leading to customer complaints and returns. By implementing a focus on “Order Picking Accuracy” as a key KPI, they invested in improved training, optimized pick paths, and implemented a quality check process. The result: a 30% reduction in picking errors within six months, leading to increased customer satisfaction and reduced costs.

Example 2: Optimizing Warehouse Throughput. A distribution center struggled with slow order fulfillment times, impacting their ability to meet customer demands. They adopted “Lines Picked per Hour” and “Shipping Cycle Time” as crucial KPIs. By identifying bottlenecks, they invested in automated picking systems, which reduced cycle times and increased overall throughput by 20% in the first year.

Conclusion

Implementing a warehouse KPI template is not just about tracking numbers; it’s about building a culture of continuous improvement and data-driven decision-making. By understanding and leveraging the right KPIs, you can transform your warehouse into a high-performing engine that drives profitability, efficiency, and customer satisfaction. Don’t let the secrets of top warehouses remain hidden – start building your own KPI template today, and unlock the potential of your warehouse! Remember to consistently review and refine your KPIs as your business evolves, and always strive for continuous improvement.